For the Engineering Practice module, I designed a proof-of-concept convertible car roof mechanism as part of a group of four. Initially this involved conducting a stakeholder analysis, understanding the needs of the manufacturer, driver and other relevant stakeholders such as passengers and pedestrians. This analysis was used to generate a product design specification, so the requirements of the car roof could be formalised.

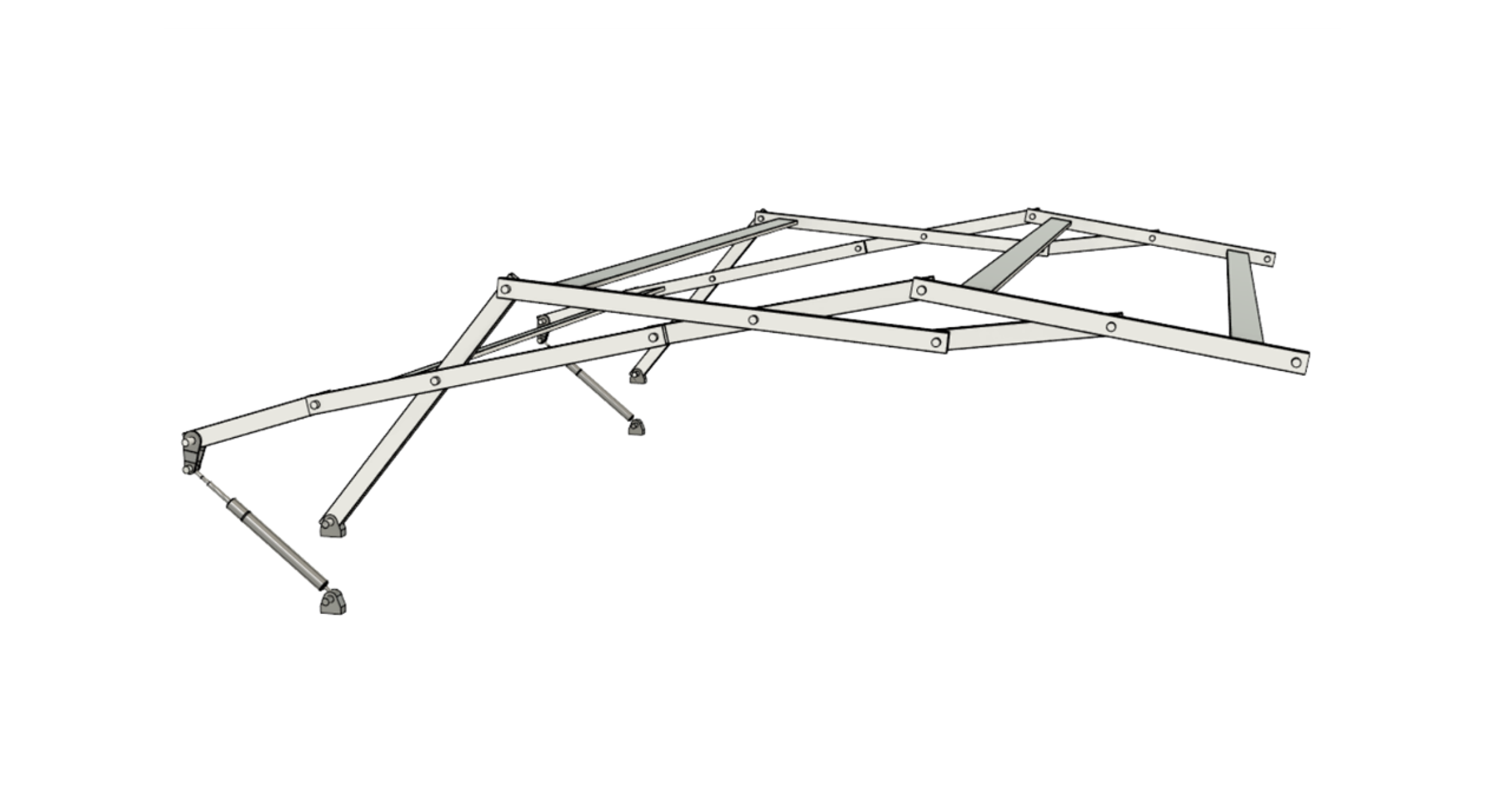

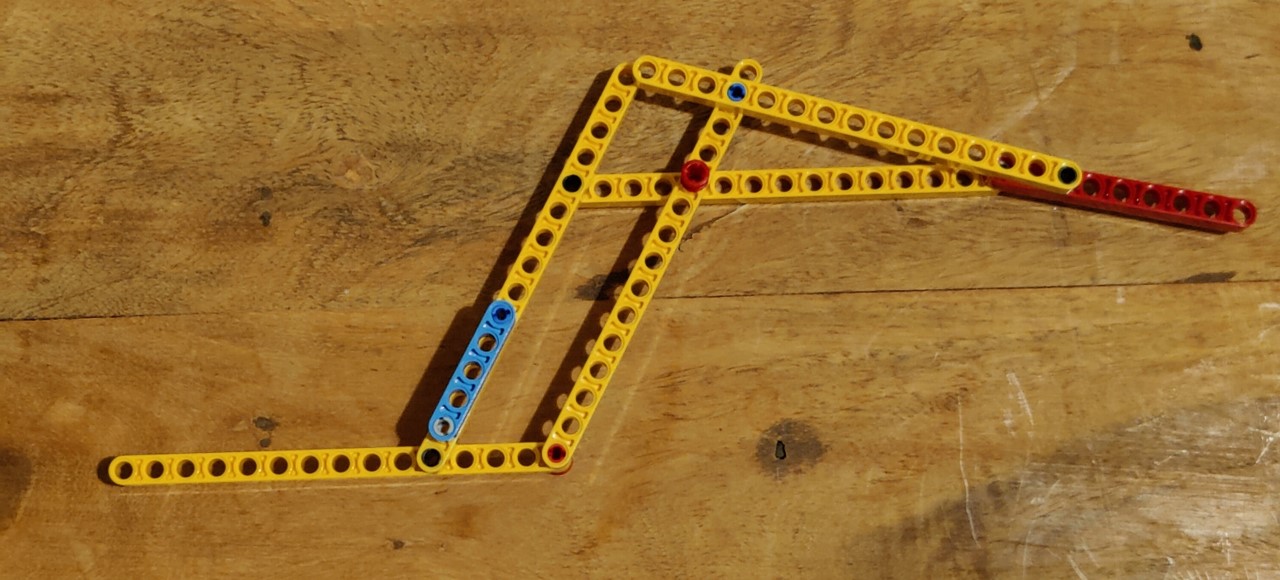

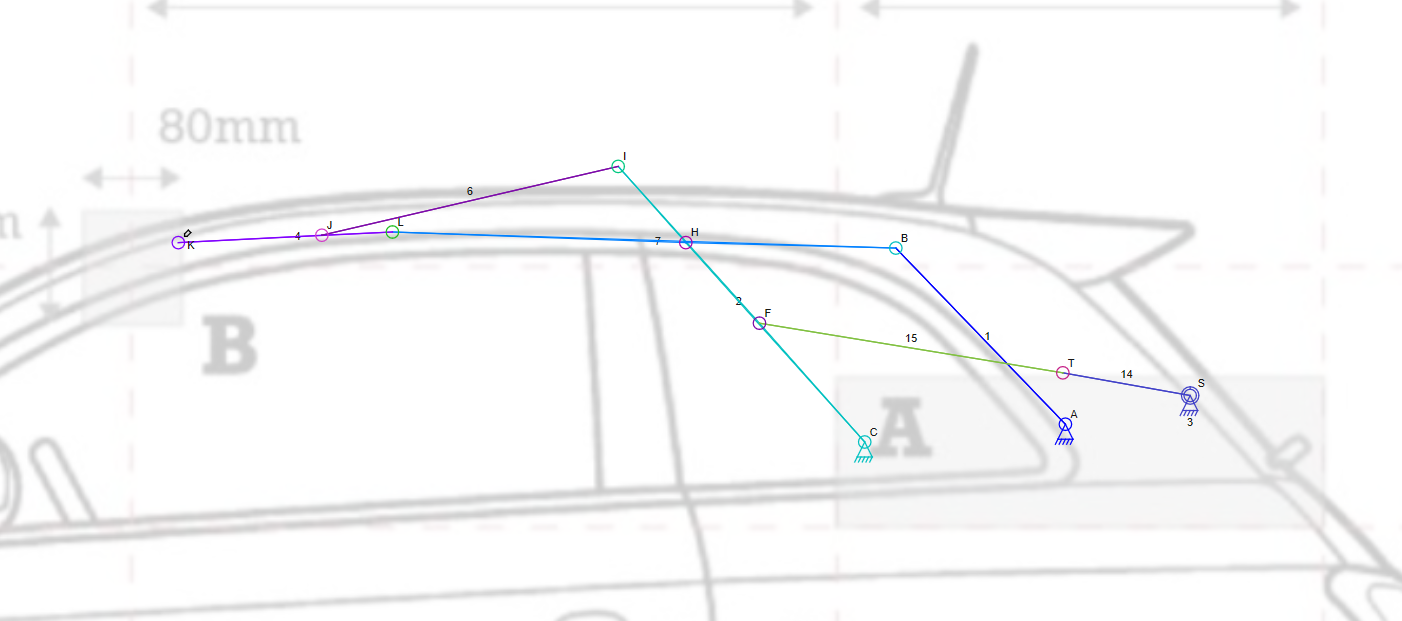

My primary role in the team was concept generation and selection. Firstly, Lego was used because it gave us the ability to rapidly generate new prototypes and gain an intuitive understanding of how the mechanism would extend and retract. An online software called ‘Linkage’ was used to generate higher fidelity prototypes, using the understanding from the Lego prototyping to constrain the design space to only realistic car roof mechanisms. Once six prototypes had been created, MATLAB was used to determine quantitative metrics for each prototype which was impossible to do as accurately in Lego or Linkage. The prototype which minimised metrics such as folded height, variation in velocity, material usage and deviation from hard-top roof shape, was chosen for further development.

Note: for the following animations, the vertical dotted lines represent the dimensional constraints for the closed roof and the other dotted lines represent the target roof shape. The blue line represents the driven rod, the red line the latching rod and the green line is the path of the latching node.