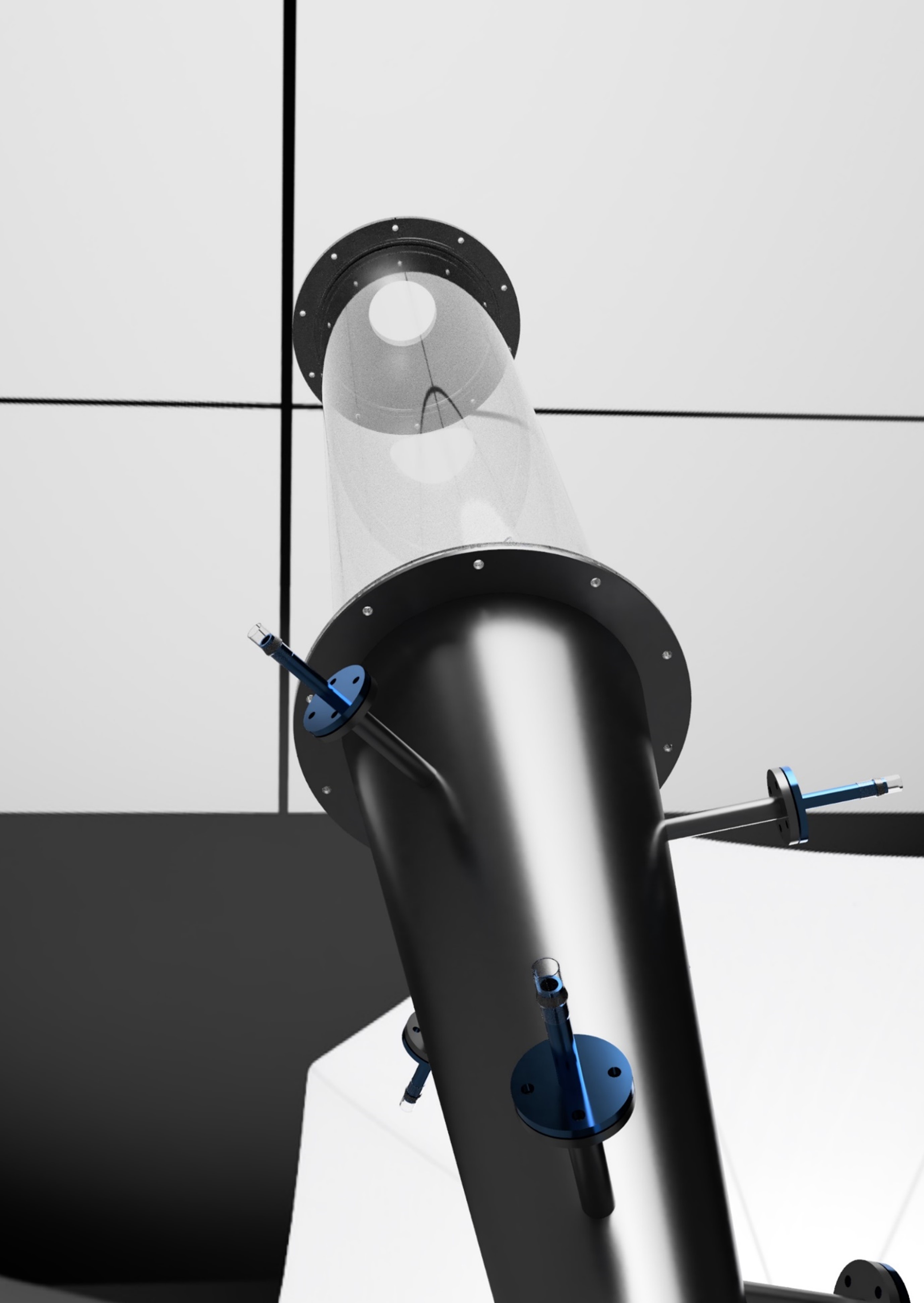

In this research project, I designed an experimental fluidised bed setup based on the hydrodynamics and functional requirements of a fluidised bed reactor – a vessel which suspends fine particles via a continual updraft of gas. Initially, this involved conducting a literature review on gas-solid flows to gain an understanding of the important parameters in the design. From these high-level requirements: achieving fluidisation, modular design, ability to remove/add solid material and structural soundness I could focus on developing the design.

Using a sample of the solid material, I used wire gauzes to separate the particles based on their diameter and weighed each fraction individually to approximate the mass fraction-to-diameter profile. From this I could then calculate the minimum velocity of the gas to achieve fluidisation and the expected behaviour of the resulting suspension. I also calculated other important flow related variables such as pressure drop, height of the setup, and then performed a finite element analysis to ensure the design fulfilled its structural requirements.

I also delved into valve selection to allow the solid material to be released from the vessel, safety aspects such as static discharge and over-pressurisation of the vessel and pressure sensor selection and placement.