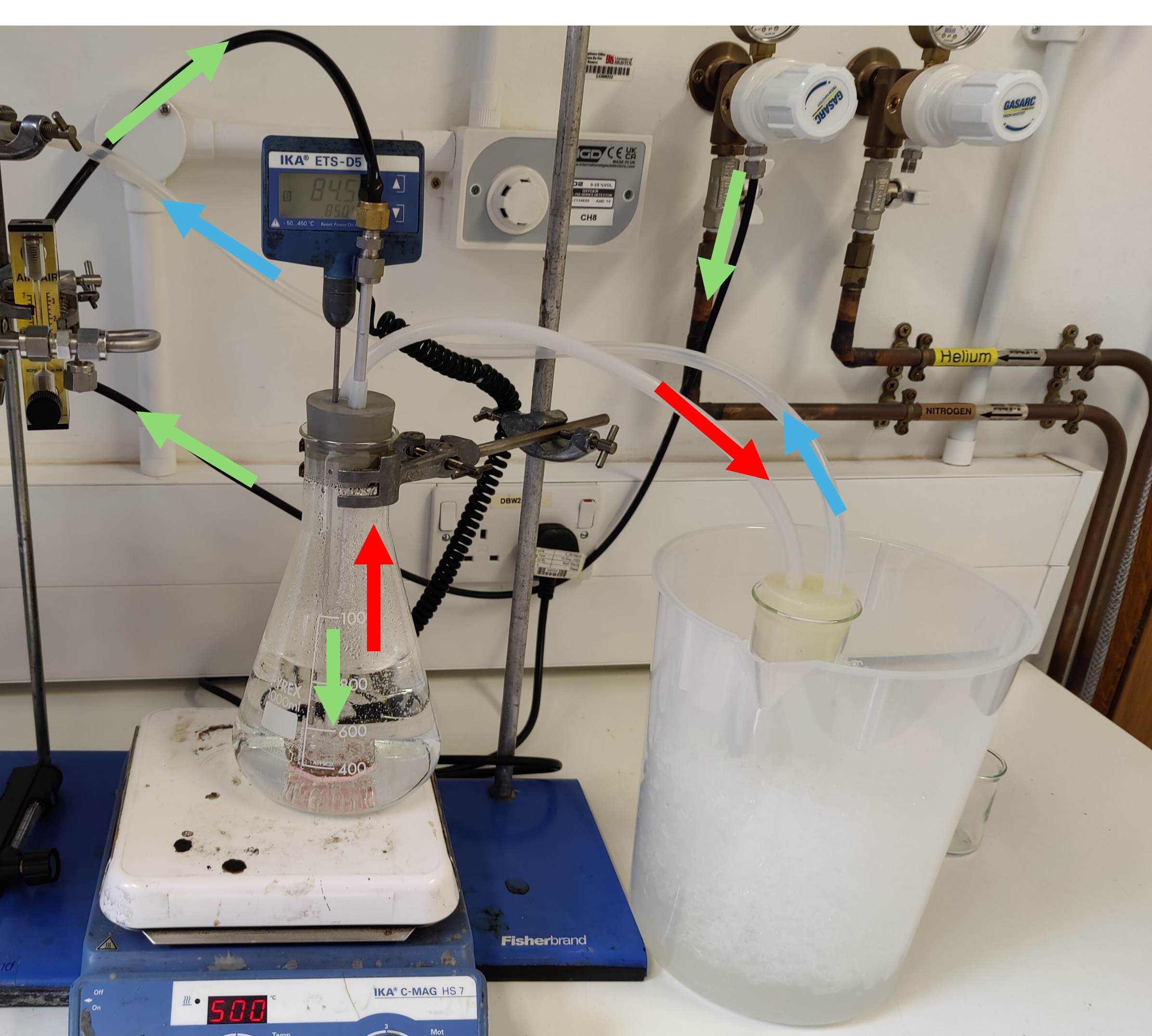

Activated carbon is a highly porous material, which enables it to be used in filtering/adsorption applications, such as water filtration or hydrogen physisorption. The aim of the project was to develop a method of generating steam, rather than the current CO2 supply, to react with the carbon sample in the furnace. My role (within the team) of five was to design and simulate the one of the two steam generator prototypes - the Bubble Humidifier - and to also simulate the chemical reaction between carbon and steam.

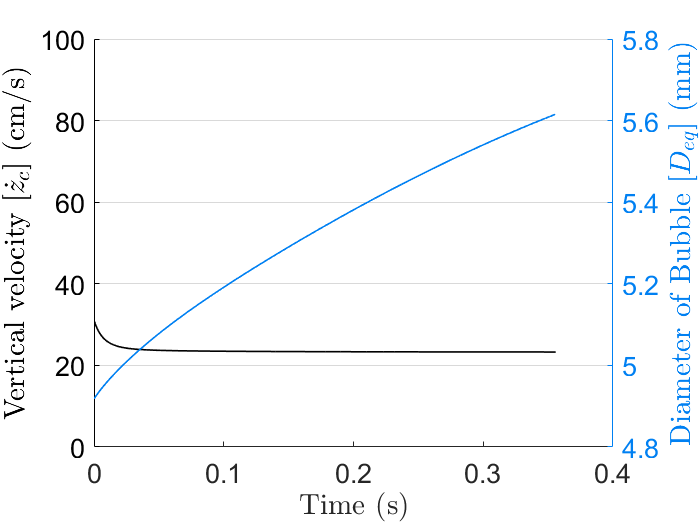

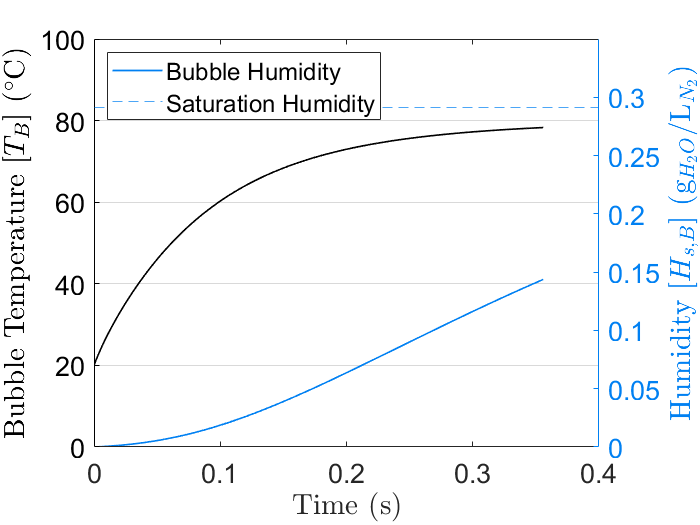

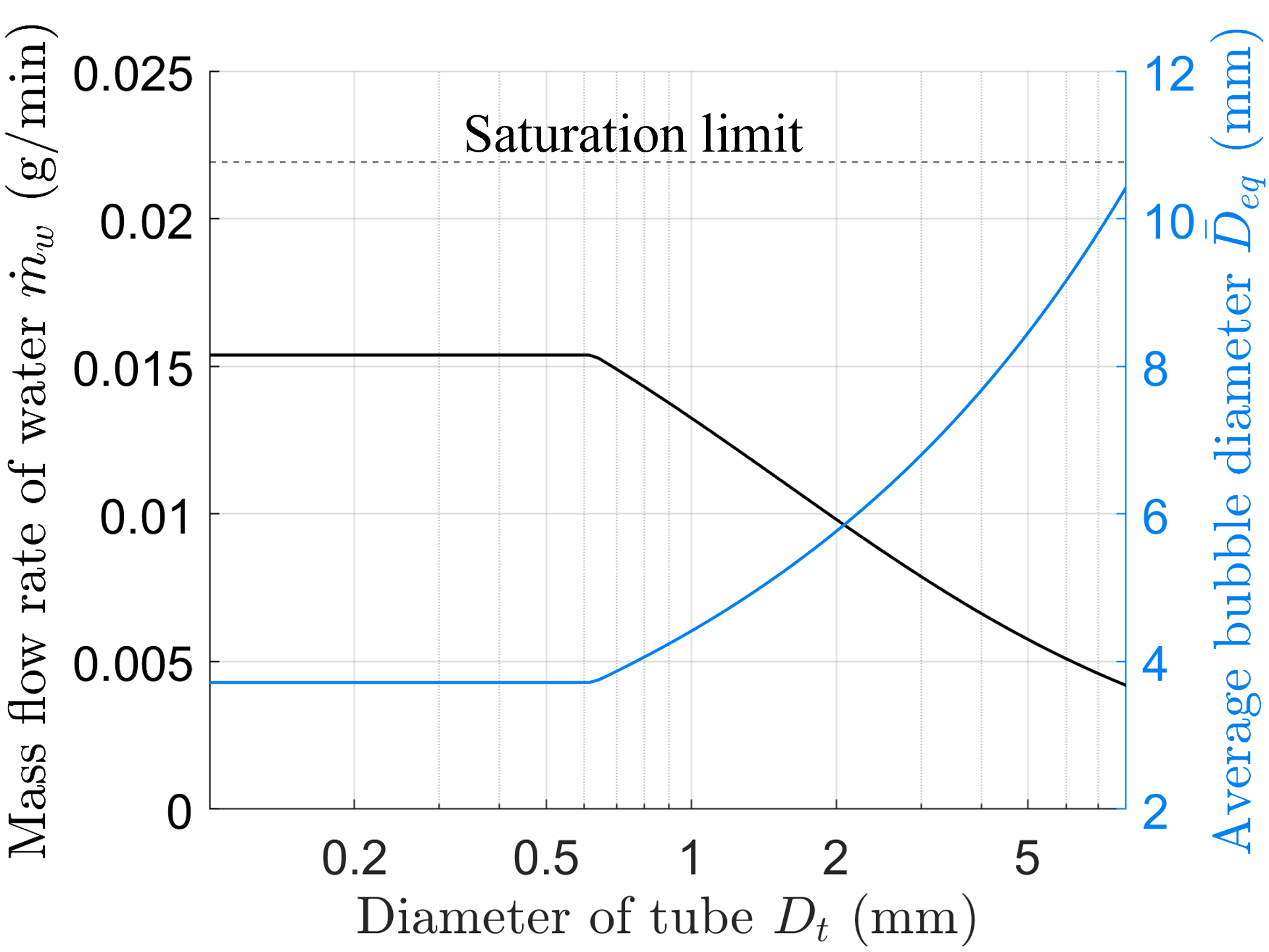

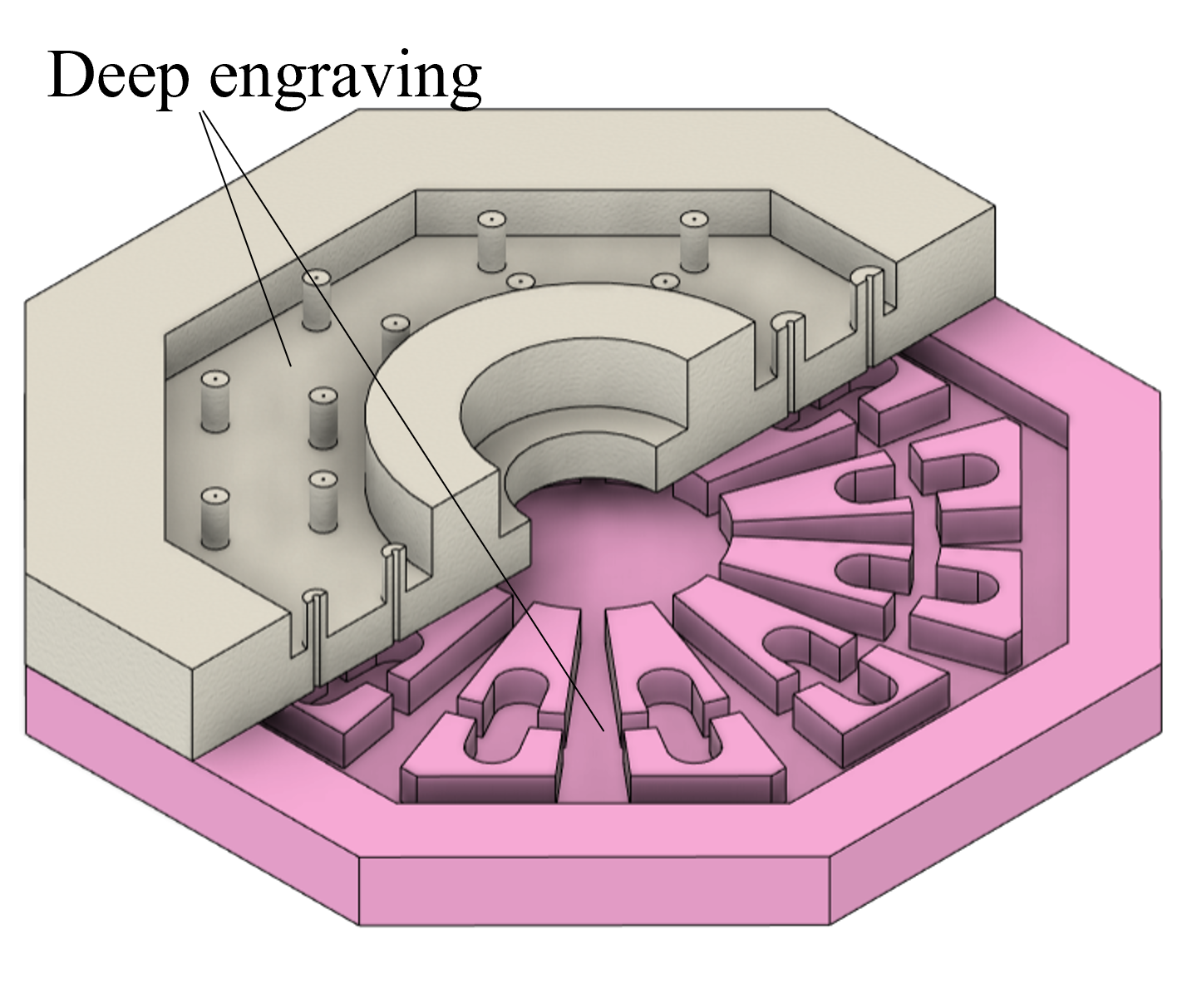

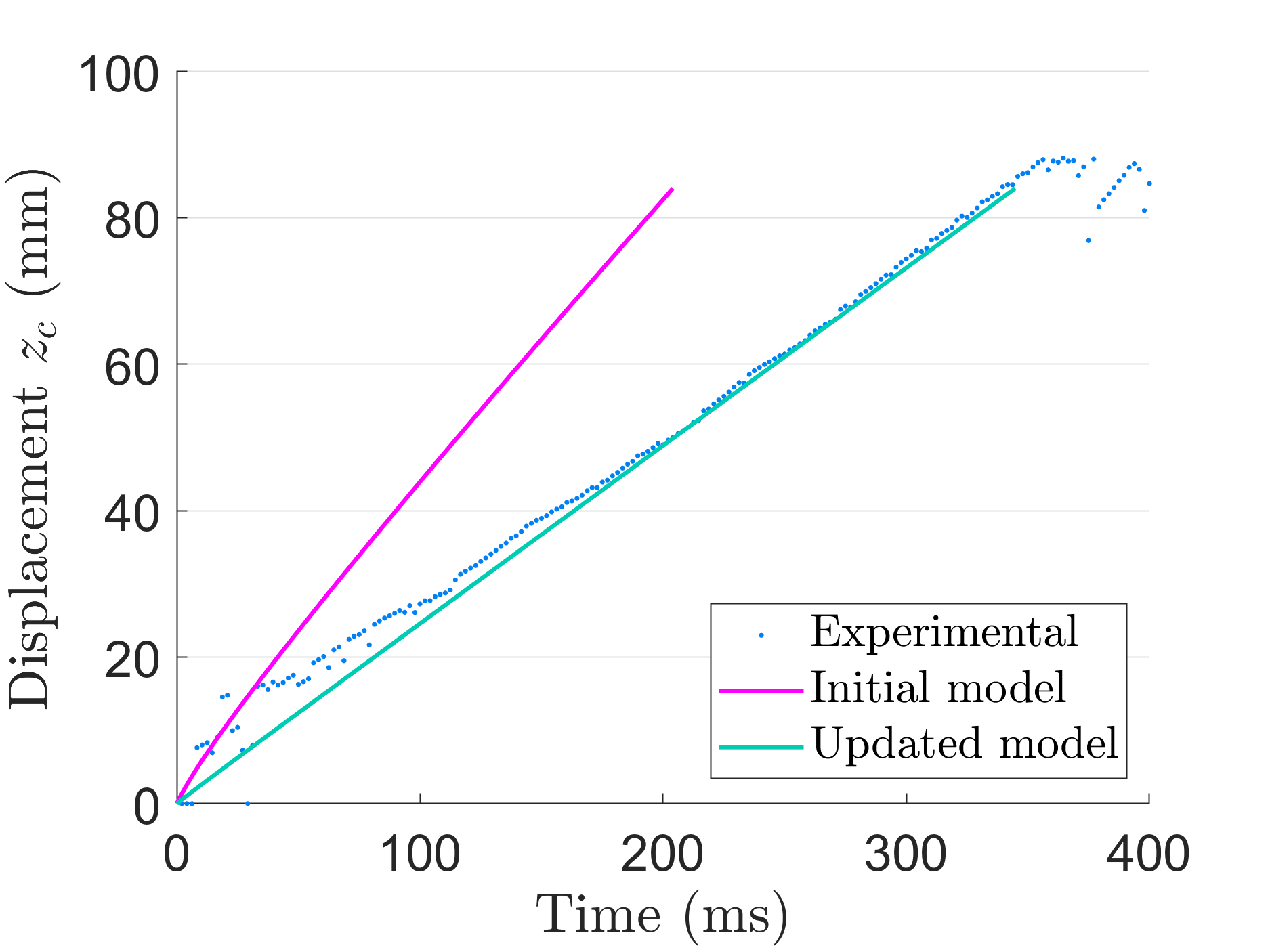

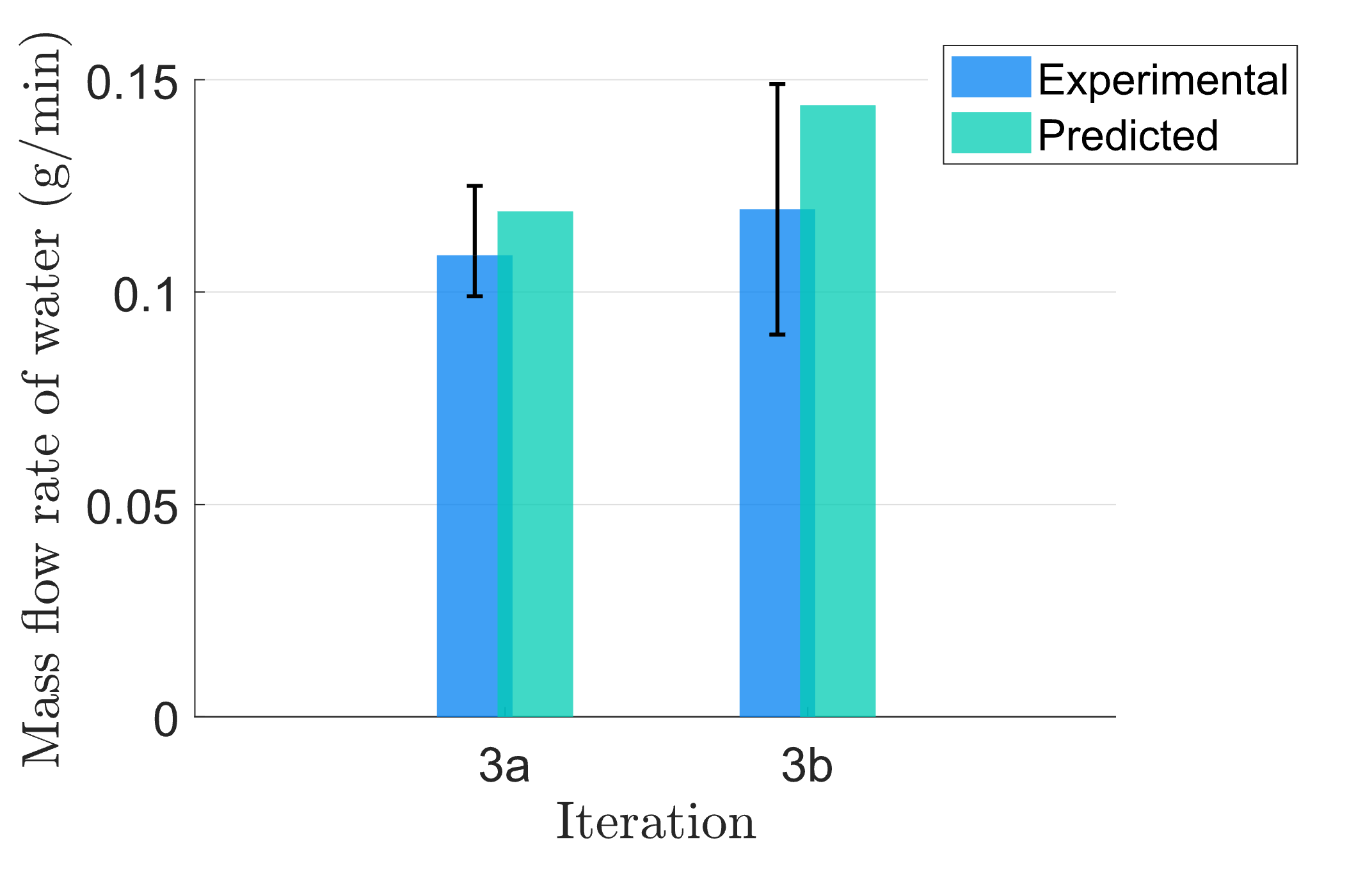

The Bubble Humidifier works by injecting nitrogen bubbles into heated water, with the water then evaporating into the bubbles and being carried into the furnace where it is superheated and reacts with the carbon. Maximising the amount of steam (or technically water vapour) the Bubble Humidifier can generate reduces the activation time and therefore experimental cost. To achieve this, an accurate model of the multiphase bubble dynamics was required. An initial model was refined using experimental data with image processing to estimate the velocity and size of the bubbles (similar to crack sizing in Non-Destructive Evaluation ) and then used to estimate the optimum activation time of the carbon. A similar process was followed to validate and refine the chemical reaction simulation, as the initial optimum activation time of 17 minutes was an underestimate compared to a more reasonable 60 minutes.

Overall, the 60 minute activation performed very similarly to the industrial carbon with a mode pore size of 7Å, so it could potentially be used for hydrogen physisorption.